AI Workforce Scheduling for Warehouses | Digital Fractal

AI workforce scheduling is transforming how Canadian warehouses manage staff by leveraging machine learning and predictive analytics. Unlike manual scheduling, these systems forecast labour needs, assign tasks based on employee skills, and adjust schedules in real time. This approach reduces costs, improves delivery times, and enhances employee satisfaction by considering preferences and enforcing compliance with Canadian labour laws. Companies adopting AI scheduling report:

- 10–20% lower labour costs through reduced overtime and better shift alignment.

- 30% faster delivery times and 12% lower fuel costs via optimized resource allocation.

- 15–30% lower turnover rates thanks to fair and flexible scheduling.

AI systems also ensure compliance with labour regulations, track certifications, and maintain detailed audit trails, reducing risks and penalties. Implementation involves integrating AI with existing systems, training staff, and balancing automation with human oversight. Canadian providers like Digital Fractal Technologies Inc. offer tailored solutions to help warehouses achieve these results within 3–9 months.

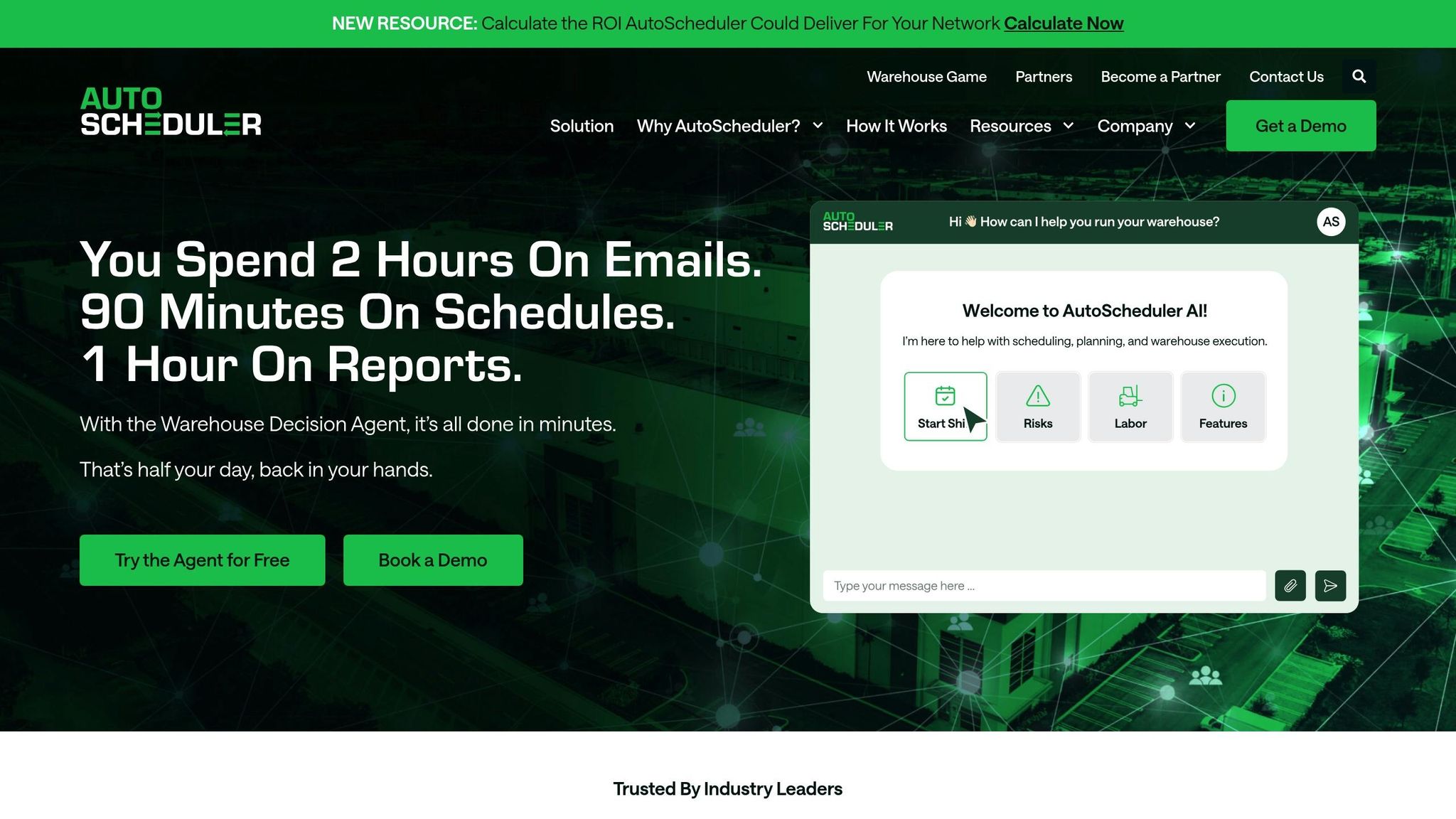

🎯 How AutoScheduler.AI Is Revolutionizing Warehouse Scheduling | Smart Warehouse Tech 🚛

How AI Workforce Scheduling Works

AI-driven workforce scheduling is reshaping warehouse operations by processing massive amounts of data and making decisions that go beyond human capabilities. These systems work 24/7, constantly analysing information and tweaking schedules to ensure seamless operations.

Data Analysis and Decision-Making

AI scheduling systems handle multiple data streams at once, using historical order data to identify patterns by time of day, day of the week, and seasonality. For example, if Mondays consistently demand extra staff or if certain weather conditions in Canadian regions cause delivery delays, the system adjusts schedules proactively.

Machine learning algorithms dig deeper into historical data to uncover trends that might slip past manual reviews. For instance, the system can identify which combinations of employees and scheduling strategies lead to better productivity. Over time, the AI learns from past results, fine-tuning its decisions to improve efficiency while supporting a healthier work–life balance.

Real-time data adds another layer of precision. By monitoring current conditions like employee availability, ongoing tasks, and warehouse activity, the AI can quickly adjust schedules to handle unexpected events. Whether it’s a sudden surge in orders, multiple sick calls, or disruptions caused by traffic or weather, the system recalculates staffing needs on the fly.

One standout feature is predictive analytics. By analysing historical patterns, seasonality, and promotional cycles, AI forecasts future labour demands with impressive accuracy. This allows managers to avoid overstaffing or understaffing and plan schedules more effectively. These insights also help balance multiple factors simultaneously, ensuring smoother operations.

Key Factors AI Considers

AI scheduling systems juggle a variety of variables that would be nearly impossible to manage manually. For example, they match tasks to employee skill levels, assigning experienced workers to complex orders while newer staff handle simpler tasks. They also take into account shift preferences, time-off requests, and availability to create schedules that are both fair and supportive of work–life balance.

In Canada, these systems are designed to comply with labour laws, automatically enforcing rules around maximum work hours, mandatory breaks, and overtime. This reduces compliance risks and lightens the administrative load for managers.

Through multi-variable optimisation, AI balances business needs with employee preferences, skill sets, and labour cost goals. This ensures warehouses meet operational demands while also boosting employee morale and reducing turnover.

Additionally, AI analyses workflows to improve efficiency. By studying processes like picking, packing, and sorting, it can recommend better routes and sequences. For instance, optimising picking paths can cut labour costs by up to 25%.

What sets AI apart is its ability to adapt in real time. This flexibility allows warehouses to respond quickly to supply chain disruptions or shifts in market demand.

Digital Fractal Technologies Inc. applies these AI capabilities in their custom software and workflow automation solutions. Their expertise in data engineering, machine learning, and AI integration helps Canadian warehouses implement scheduling systems tailored to local operational needs and regulations.

Key Benefits of AI Workforce Scheduling

Canadian warehouses are seeing noticeable improvements in financial performance, day-to-day operations, and employee satisfaction thanks to AI-driven workforce scheduling.

Cost Savings

AI scheduling tools are a game-changer for cutting costs in warehouse operations. One major area of savings is overtime reduction. By accurately forecasting staffing needs and fine-tuning shift patterns, AI helps warehouses avoid costly overtime pay. For instance, Canadian logistics companies have managed to cut labour costs by 10–20% simply by better aligning shifts and reducing overtime.

Another cost-saving perk is administrative efficiency. Managers who use AI tools for scheduling spend up to 80% less time on this task. That freed-up time allows them to focus on more strategic priorities rather than getting bogged down in the complexities of schedule creation.

AI also helps with employee retention, which significantly lowers turnover costs. Predictable and fair scheduling reduces burnout, leading to 15–30% lower turnover rates. Considering that replacing a single warehouse worker can cost between $3,000–$5,000 CAD in recruitment and training, this improvement adds up quickly.

But AI doesn’t just save money – it also boosts how well warehouses run.

Improved Productivity and Performance

AI takes warehouse productivity to the next level by ensuring tasks are assigned to the right people. By matching employee skills and certifications to specific jobs, AI reduces errors and increases throughput. For example, one Canadian warehouse reported a 22% drop in picking labour costs and a 15% boost in order throughput within just a year of adopting AI-based job optimization.

Workflow enhancements are another big win. AI can analyze picking paths, packing sequences, and sorting processes to identify inefficiencies. These insights can cut picking labour costs by as much as 25% while improving order accuracy.

The speed improvements are hard to ignore. Warehouses using AI scheduling have reported up to a 30% reduction in delivery times and a 12% decrease in fuel costs, thanks to smarter route planning and resource allocation.

AI also shines when unexpected challenges arise. Its real-time adaptability allows it to quickly adjust staffing and task assignments in response to equipment failures, sudden surges in orders, or unexpected absences, ensuring operations stay on track.

Better scheduling also leads to fewer errors. Well-rested, properly skilled workers make fewer mistakes, which means fewer product returns, less rework, and happier customers. The combination of faster and more accurate operations gives warehouses a competitive edge that goes beyond just meeting deadlines.

Employee Well-Being and Retention

For Canadian workers, where fair scheduling and work-life balance are highly valued, AI scheduling offers a much-needed solution.

One standout advantage is schedule fairness. AI ensures that both popular and less desirable shifts are distributed more equitably, eliminating favouritism and giving employees greater transparency.

AI also improves work-life balance by taking into account employee preferences, availability, and time-off requests while still meeting operational needs. This leads to higher job satisfaction and less stress for workers.

Burnout decreases as AI ensures adequate rest periods between shifts and enforces labour laws regarding breaks and maximum working hours. These systems not only protect employee health but also ensure compliance with Canadian employment standards.

Physical strain is another area where AI makes a difference. By identifying opportunities to automate repetitive tasks and rotating workers through different activities, it helps reduce the risk of injuries and keeps employees engaged during their shifts.

AI even supports career development by tracking employee skills and recommending training opportunities. Workers gain clarity on how advancing their skills can lead to better shifts, more responsibilities, and career growth.

All these improvements create a positive work environment while reducing overall labour costs.

Digital Fractal Technologies Inc. is at the forefront of bringing these AI benefits to Canadian warehouses. Their custom workforce management solutions integrate AI scheduling with workflow automation, ensuring compliance with local labour laws and respecting the importance of work-life balance in Canada.

Compliance and Risk Management

Warehouses in Canada operate under a web of federal and provincial labour regulations, and failing to comply can lead to hefty financial penalties. AI-driven workforce scheduling systems provide a reliable way to navigate these rules by automatically embedding compliance into scheduling processes, reducing the risk of violations and creating a more secure scheduling framework.

These systems integrate legal requirements from the Canada Labour Code and provincial employment standards directly into their algorithms. This ensures schedules adhere to limits on maximum working hours, overtime pay, and mandatory rest periods. The AI continuously monitors schedules, flags potential issues, and makes real-time adjustments to keep operations within legal boundaries – even when last-minute changes arise.

The financial stakes are high. Non-compliance penalties can cost thousands of dollars per infraction. Beyond fines, warehouses may face back pay orders, legal battles, and reputational harm, which could make it harder to attract and retain employees.

Adding to the complexity, union agreements and collective bargaining rules often impose additional scheduling requirements. AI platforms can adapt to these, promoting fairness and reducing grievances. This capability directly supports the goal of mitigating compliance risks across all areas.

Another critical feature of these systems is their ability to maintain detailed audit trails. These records are invaluable during inspections or disputes, as they demonstrate adherence to labour standards and help streamline regulatory audits. Moreover, AI tools can enhance workplace safety by tracking employee certifications and assigning tasks only to qualified workers.

Companies like Digital Fractal Technologies Inc. specialize in developing AI solutions tailored to the unique challenges of Canadian warehouses. Their expertise in custom software ensures seamless integration with existing warehouse management systems while prioritizing compliance with local labour laws.

To make the most of these systems, warehouses must regularly update them to reflect changes in regulations. Equally important is staff training – managers need to understand how to interpret AI-generated alerts and recommendations. This human oversight is essential to maintaining both compliance and operational efficiency. Together, these measures lay the groundwork for consistent operations that align with the broader efficiency benefits discussed in this guide.

sbb-itb-fd1fcab

Implementation Guide for Warehouse Managers

Deploying AI workforce scheduling in a warehouse setting demands careful planning, technical integration, and consistent oversight. While the process typically spans several months, many organizations see a positive return on investment within 3 to 9 months of full deployment.

Integration with Existing Systems

The backbone of a successful AI scheduling system lies in its ability to integrate seamlessly with your current warehouse tools and processes. Start with a thorough audit of all systems that need to work alongside the AI platform – this includes your Warehouse Management System (WMS), payroll software, time and attendance systems, and HR tools.

To make this work, data compatibility is crucial. The AI platform needs accurate information, such as employee details, shift definitions, certifications, and historical scheduling data. Define how data will flow between systems using API connections for real-time updates. For example, if your WMS detects a spike in order volume, the AI system should immediately adjust staffing recommendations to match demand.

Typically, integration takes 4-8 weeks to configure and connect systems. During this time, focus on data quality – standardize job titles, certifications, and availability across platforms. Poor data can lead to unreliable scheduling outcomes.

Before fully switching to AI scheduling, plan for a parallel run where both the current and AI systems operate simultaneously. This phase allows you to verify the AI’s accuracy and reliability, ensuring it produces schedules that align with operational needs.

For added support, companies like Digital Fractal Technologies Inc. specialize in software development and AI integration tailored to Canadian warehouses. Their expertise can help ensure your system complies with local labour laws while connecting seamlessly with your existing setup.

A well-executed integration sets the stage for effective training and smoother adoption.

Training and Change Management

One of the biggest hurdles in adopting AI scheduling is employee resistance, often rooted in concerns about job security. Address these fears through open communication, highlighting the benefits: better workload distribution, more flexible schedules, and opportunities to upskill into more engaging roles.

Involve key stakeholders – like supervisors, team leads, and employee representatives – early in the process. Let them participate in system demonstrations and provide feedback. This collaborative approach fosters trust and helps preempt potential issues.

Training should be tailored to specific roles and typically takes 2-4 weeks. Warehouse managers need to learn how the AI system works – how it analyses data, forecasts demand, and generates scheduling recommendations based on employee preferences and operational needs. Managers should also become comfortable with predictive analytics dashboards, understanding when to accept or override the AI’s suggestions.

Supervisors, on the other hand, require hands-on training to manage real-time changes, exceptions, and schedule adjustments. They should also understand how the system enforces Canadian labour laws, union agreements, and company policies to reduce compliance risks.

Rolling out the system in phases – starting with one shift or department – can help resolve issues early. Celebrate small successes, like reduced overtime costs or improved work-life balance, to build momentum and encourage buy-in from the broader team.

Balancing AI with Human Oversight

Once the system is integrated and teams are trained, the focus shifts to striking the right balance between AI-driven insights and human judgment.

AI can handle routine scheduling efficiently, especially in scenarios with stable demand patterns. However, unexpected challenges – like equipment breakdowns, supply chain disruptions, or special customer requests – require human intervention. Managers must retain the authority to override AI recommendations when needed.

Establish clear protocols for overrides, including documenting the reasons behind them. This feedback helps the AI system learn from human expertise and refine its future recommendations. Transparency is key – the AI should explain its scheduling decisions, highlighting factors like demand forecasts, employee preferences, or compliance rules. This helps managers decide when to trust the system and when to intervene.

A tiered approval process can further streamline operations. Routine schedules can be auto-approved, while complex or high-impact decisions require managerial review. This approach balances efficiency with the need for oversight.

The time saved by automating routine tasks should be reinvested in strategic activities like employee development, exception management, and process improvement. Managers should also have clear escalation procedures for handling critical issues that the AI system cannot resolve. Define authority levels for manual changes and ensure managers know who to contact when exceptions exceed their scope.

Regularly reviewing exception logs can uncover patterns and highlight areas where the AI system might need adjustments. Work with your implementation partner to refine algorithms or update business rules as needed. Maintaining a knowledge base of past exceptions and their resolutions can also help new managers navigate similar challenges effectively.

Measuring Success and ROI

Once your AI workforce scheduling system is up and running, evaluating its performance is essential. Not only does this confirm that your investment was worthwhile, but it also highlights areas where further tweaks might enhance efficiency. By focusing on measurable outcomes that directly affect your warehouse’s financial performance and operational processes, you can clearly demonstrate the system’s overall value.

Key Performance Indicators (KPIs)

To measure success effectively, rely on specific KPIs that reflect both operational efficiency and workforce stability. These metrics should align with your business objectives and allow for straightforward comparisons before and after implementation.

One of the most telling indicators is labour cost reduction. Track all labour-related expenses in CAD, including wages, overtime, and temporary staffing. According to recent case studies, AI-driven workforce scheduling has helped companies cut labour costs by 10–20%.

Another vital metric is on-time delivery rates, which show how consistently your warehouse meets shipping deadlines. Calculate this as a percentage of total orders shipped on schedule. AI scheduling has been shown to boost delivery times by as much as 30%.

Employee turnover rates offer a window into workforce satisfaction and stability. Monitor the percentage of employees leaving annually. AI systems that consider worker preferences and reduce scheduling conflicts often lead to better retention, cutting down on recruitment and training costs.

Customer satisfaction scores are another key metric, revealing how operational improvements impact service quality. Collect feedback through post-delivery surveys or customer service interactions. Warehouses that are well-staffed and efficient typically see higher satisfaction levels, thanks to faster processing and fewer errors.

Other metrics worth tracking include overtime hours per employee, absenteeism rates, and productivity measures like orders fulfilled per labour hour. For Canadian warehouses, it’s critical to report all financial data in CAD and factor in local wage rates when calculating savings. Additionally, ensure compliance with provincial labour laws and union agreements as part of your overall performance tracking.

Establishing Baseline Metrics

Accurate measurement starts with establishing solid baseline data before introducing AI. Without this, it’s challenging to quantify the system’s impact or calculate ROI.

Begin by collecting a full year of historical data for your KPIs. This will account for seasonal fluctuations and provide a complete picture of your warehouse’s typical performance. Record metrics like average labour costs, delivery times, employee turnover rates, and customer satisfaction scores. Use Canadian date formats (YYYY-MM-DD) and metric units for consistency.

Document your current scheduling practices in detail. Track how much time managers spend creating schedules, how often last-minute changes occur, and the percentage of shifts requiring overtime. Also, record any compliance issues, employee grievances related to scheduling, and penalties for labour law violations.

For financial baselines, break down labour costs into wages, overtime, temporary staffing, and recruitment. Note any seasonal trends or unique circumstances, such as holiday surges, that might affect normal operations.

Operational baselines should include order processing times, shipping accuracy rates, and equipment usage. Assess how current staffing levels influence throughput at different times and identify recurring bottlenecks.

To establish employee satisfaction baselines, use surveys or exit interviews. Collect feedback on scheduling fairness, work–life balance, and shift preferences. Track metrics like sick leave usage and voluntary overtime participation to gauge overall job satisfaction.

These baseline metrics are essential for calculating ROI. Use the following formula tailored for Canadian operations:

ROI = (Net Benefit ÷ Total Costs) × 100%

Here, Net Benefit includes total savings and revenue gains minus implementation and ongoing costs, all expressed in CAD. Include costs like software licensing, integration, training, and hardware in your calculations.

Most businesses using AI scheduling systems report achieving positive ROI within 6–12 months. Logistics operations, for example, have seen 12% lower fuel costs alongside labour savings. Reduced overtime, improved retention, and increased productivity often combine to deliver returns that easily justify the initial investment.

For Canadian warehouses looking for tailored AI solutions, Digital Fractal Technologies Inc. provides custom AI-driven systems, including KPI dashboards and performance tracking tools. Their expertise in workflow automation and digital transformation ensures compliance with local regulations while optimising operational efficiency.

Conclusion

AI-driven workforce scheduling is reshaping how Canadian warehouses operate, leaving behind outdated manual processes in favour of smarter, more adaptable systems. Warehouses are consistently reporting improvements in areas like labour costs, delivery times, and fuel usage, which translates into real advantages in Canada’s competitive logistics market.

With these benefits in mind, Canadian warehouse managers have a clear opportunity to plan their transition. As highlighted earlier, this shift creates a win-win situation: better operational efficiency and higher employee satisfaction. Workers gain from predictable schedules, fewer overtime demands, and access to skill-building opportunities. Meanwhile, managers are freed from the time-consuming task of manual scheduling, allowing them to focus on strategic priorities – all while maintaining productivity and keeping employees engaged.

For those ready to adopt this technology, success hinges on thoughtful integration. This means aligning AI with existing systems, ensuring proper training for staff, and keeping human oversight in place to handle unique scenarios. The companies achieving the best results are those that see AI as a tool to complement human expertise, not replace it.

Many warehouses report a positive return on investment within 3–9 months, making AI workforce scheduling a practical and timely choice. Such results highlight the importance of working with experienced providers to maximize the value of this technology.

Digital Fractal Technologies Inc. offers customized AI solutions designed to help Canadian warehouses meet compliance standards and improve operational efficiency. With their proven expertise in digital transformation across industries like logistics and energy, they provide the technical support and guidance needed for long-term success.

FAQs

How can AI workforce scheduling reduce labour costs and improve delivery times in Canadian warehouses?

AI-driven workforce scheduling is transforming how Canadian warehouses manage their operations. By analysing demand forecasts, task priorities, and operational constraints, these systems help create smarter employee schedules. The result? Fewer workers during slower periods and enough hands on deck during busy times, which directly cuts down on labour costs.

Beyond balancing staff levels, AI can also fine-tune resource allocation. Tasks like inventory management and order fulfilment are handled more efficiently, ensuring quicker deliveries and happier customers. Over time, these improvements translate into boosted productivity and noticeable cost savings for warehouses across Canada.

How can AI workforce scheduling systems be integrated with existing warehouse management systems?

Bringing AI workforce scheduling into your existing warehouse management setup involves a few key steps to ensure everything runs smoothly. Here’s how to get started:

First, take a close look at your current systems to figure out how well they align with the AI solution. This step is all about pinpointing compatibility and identifying where integration will be most effective. The goal is to make sure the AI system blends seamlessly with your workflows and data structures.

Next, work alongside your AI provider to tailor the system to fit your operations. This might involve setting up data pipelines, defining specific scheduling rules, and teaching the AI how your warehouse operates. Don’t skip the testing phase – this is where you confirm that the integration is accurate and efficient before going live.

Lastly, ensure your team is ready to use the new system. Training is essential for a smooth transition. While AI workforce scheduling has the potential to boost productivity, streamline labour allocation, and cut costs, its success hinges on how well your team adopts and uses it.

How does AI help warehouses comply with Canadian labour laws while improving employee satisfaction?

AI-driven workforce scheduling simplifies the challenge of staying compliant with Canadian labour laws. It automates intricate tasks like aligning schedules with provincial rules on working hours, overtime caps, and mandatory break periods. This not only minimizes the chance of human error but also helps businesses steer clear of costly penalties.

Beyond compliance, AI contributes to employee satisfaction by generating fair and efficient schedules. It takes into account factors like personal preferences, skill sets, and availability. By balancing workloads and respecting individual needs, AI helps create a workplace that’s both harmonious and productive – especially in warehouse operations.